General introduction

General introduction

1. General introduction of our Aluminum Honeycomb Panel (AHP)

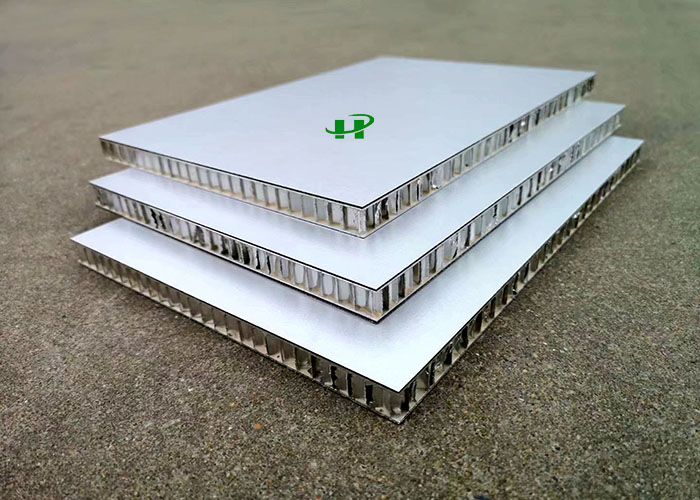

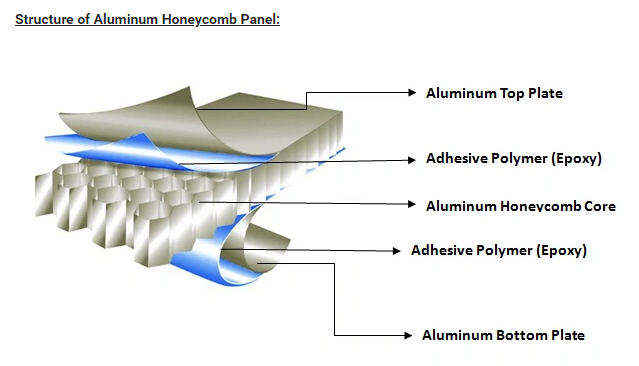

Base Structure

Main Advantages

|

1 |

Sound Insulating, Heat Insulation, Heat Preservation |

|

2 |

Fireproof Properties: A1/ A2/ B1 |

|

3 |

Super Flatness, Rigidity and Durable |

|

4 |

Moisture Resistance, Corrosion Resistant |

|

5 |

Light weight and energy saving |

|

6 |

Environmental recyclable |

|

7 |

Easy installation |

Technical Data

|

Technical Data Of HONGZAN Honeycomb Panels |

|||

|

Testing samples: |

|||

|

Thickness |

20mm |

25mm |

|

|

Aluminum Top Plate |

1.00mm |

||

|

Aluminum Bottom Plate |

1.00mm |

||

|

Weight (kg/m²) |

7.4 |

7.8 |

|

|

Mechanical Property: |

|||

|

Inertia Moment I(cm4/m) |

19.85 |

31.67 |

|

|

Section Modulus W (cm³/m) |

19 |

24 |

|

|

Rigidity E.I (KN cm2/m) |

139000 |

2217000 |

|

|

Aluminum profile |

AA 5754A(ALMg3) |

||

|

Modulus of Elasticity (N/mm2) |

70000 |

||

|

Tensile Strength of facing panel (N/mm2) |

Rm ≥ 220 |

||

|

0.2% Yield Stress(N/mm²) |

Rp0.2 ≥ 130 |

||

|

Extensibility (EN485-2:1194) |

A50 ≥ 8 |

||

|

Aluminum linear thermal expansion |

2.4mm/m when the temperature difference is 100ºC |

||

|

Surface decoration layer |

PVDF Spray Baking finish |

||

|

Glossiness (original Data) |

30-40% |

||

|

Hardness of pencil |

HB-F |

||

|

Core of Honeycomb: |

|||

|

Size of honeycomb |

1/4''(6.3mm) |

||

|

Density |

About 80kg/m2 |

||

|

Compression strength (MILL-STD-401) |

4N/mm2 |

||

|

Function Of Acoustics: |

|||

|

Data of sound absorption As |

0.05 |

||

|

Factor of sound insulation According to ISO717-RW |

23 |

25 |

|

|

Function Of Heating: |

|||

|

Data of Heat Conduction λ* (w/m2k) |

2.25 |

2.7 |

|

|

Data of Thermal Insulation R(1/m) |

0.0089 |

0.0093 |

|

|

Data of Heat Transmission U(k) (w/m2k) |

5.59 |

5.575 |

|

Specifications

|

Total Thickness |

General: 6mm,12mm,15mm,20mm,25mm,30mm Range: 6mm – 500mm |

|

Top / Bottom aluminum plate thickness |

General: 0.5mm,0.7mm,1.0mm Range: 0.4mm – 3.0mm |

|

Size |

General: 1.2m X 2.4m Maximize: 2m X 10m |

|

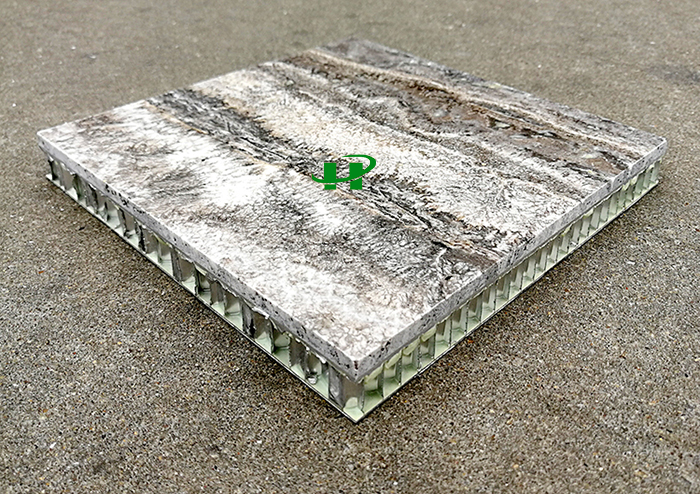

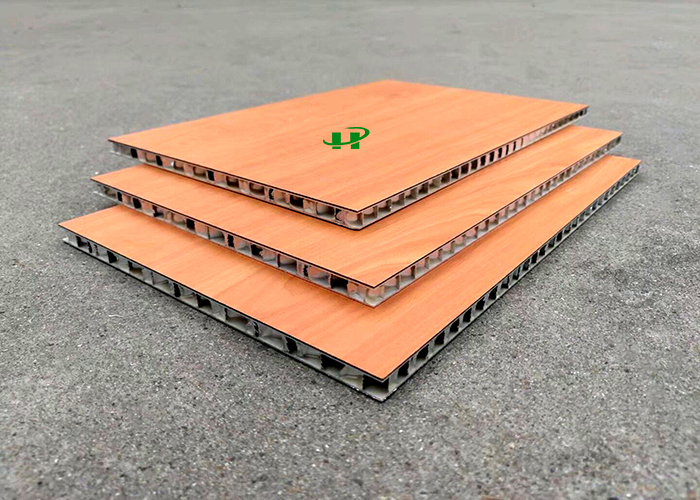

Surface texture |

None, RAL color, Wood like, Stone like, Smooth, Rough, etc |

|

Surface Treatment |

Spray, roller-coating, wire-drawing, composited with wood slice, ceramics slice, marble slice, PVC,HPL,FRP, etc |

|

Edge Processing |

Edge closed or Edge Open |

|

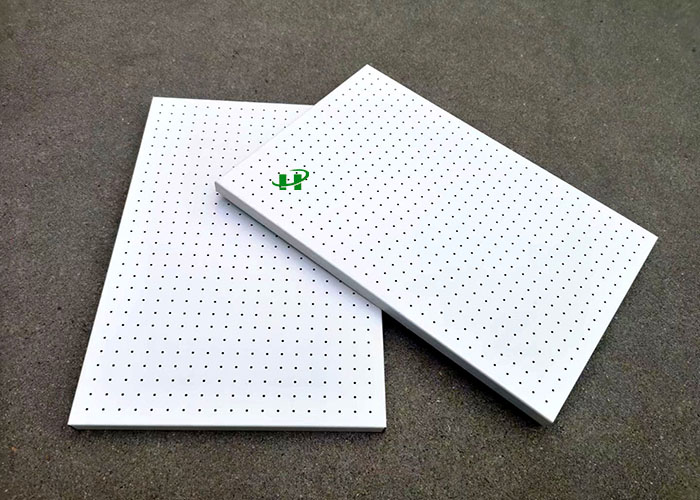

Perforation |

Yes(customized) |

|

Customization |

Yes (color, surface texture, size, shape, pattern, etc. ) |

|

Suggestion |

1. For interior wall (PE coating): Range from 8mm to 20mm (top plate: 1.0mm; Bottom plate: 0.7/0.8mm)

2. For exterior wall (PVDF coating): 15mm, 18mm, 25mm (top plate: From 1.0mm to 1.5mm; Bottom plate: From 0.7mm to 1.0mm) |

Application:

Curtain wall; exterior & interior decoration, ceiling & flooring, partitions, door & cabinet, lift & elevator; train & high speed subway; luxury ship & vehicle, etc.

Some samples: