General Introduction

General Introduction

1. Product Introduction

Basic Information:

Aluminum Corrugated Composite Panel is a high-class building and decorative

materials laminated with high-temperature adhesive film and aluminum corrugated

core. It is a new, light-weight and ECO building materials. The advantages of

Aluminum Corrugated Panel are rigidity, super flatness, good fire-resistance,

strong strength.

Material:

For aluminum sheet: Aluminum Alloy 3003H16-H18

For aluminum corrugated core: Aluminum Alloy 1100H16/H24

Specification:

|

Regular Size (W*L*T) |

1,220*2,440*6 mm |

|

Max. Size(W*L*T) |

1,600*12,000*30 mm |

|

Regular Thickness |

4/6/8/10/12/15 mm |

|

Available Thickness |

4 - 15 mm |

|

Corrugated Core Thickness |

0.2 - 0.5 mm |

|

Regular Surface Treatment |

PVDF, PE, Powder Coating, Anodized, etc. |

|

Perforation |

Yes (customized) |

|

Applications |

Ceiling, Roofing, interior decoration of train, bus, ship, truck body, etc. |

|

Customerization(MTM) |

Yes (color, surface texture, size, shape, pattern, etc.) |

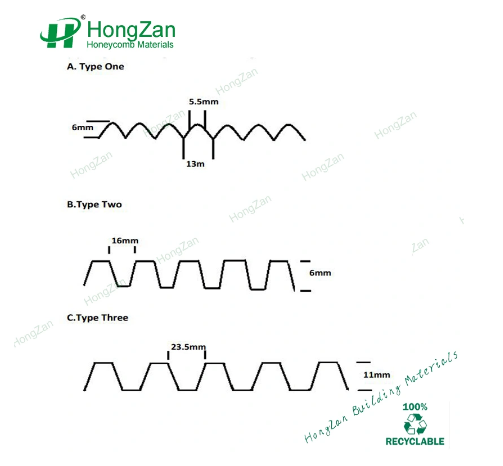

Hongzan Existing Mould of Corrugated Core:

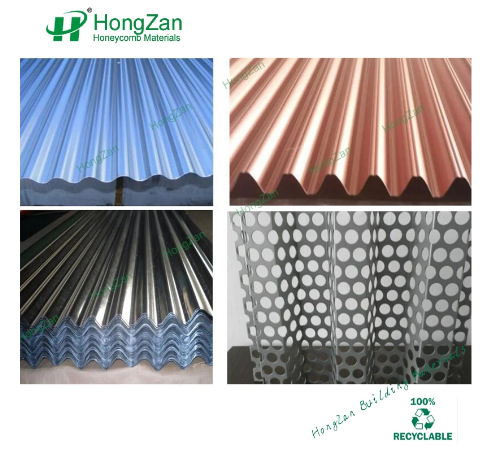

Different Kinds of Corrugated Core:

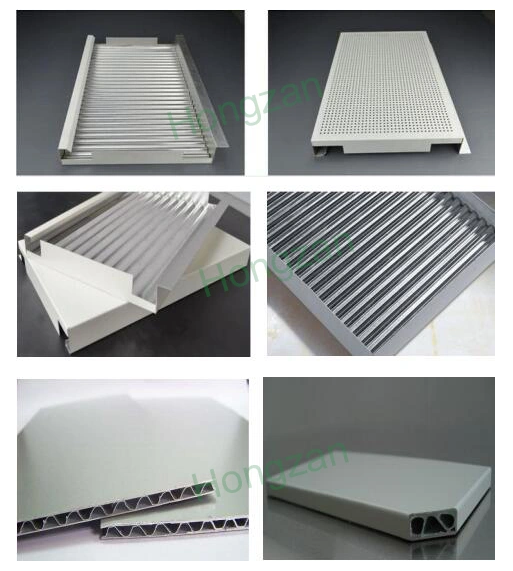

Different Kinds of Aluminum Corrugated Composite

Panel:

2. Application:

Compare with solid aluminum sheet, the flatness and rigidity

of aluminum corrugated composite panel will be much stronger because of the

corrugated core inside. The various applications of aluminum corrugated

composite panel are as below.

* ceiling

* roofing

* container house

* interior decoration of train, bus, ship

* truck body

* other indoor and outdoor application

3. Certificates:

Hongzan has obtained international recognized certificates

and test reports for aluminum honeycomb panel related to Fire rate, sound

insulation, and so on, E.G.:

1), ISO 9001:2008;

2), A class fire rate by Lloyd's ( Marine

Association) ;

3), BS 476 ,475 by TUV PSD Singapore;

4), EN13501-1 by ITS;

5), ASTM by ITS.